Hydrodynamic Treadmill

Introduction

Understanding the transport of crude oil through marine environments is vital, especially considering the long-term effects of oil spills. Oil spills are governed by complex physical and biochemical phenomena, and the study focuses on microscopic immiscible oil droplets that significantly contribute to the fate of spilled oil. This research highlights the uncertainty surrounding the total amount of biodegraded spilled oil and aims to bridge the gap between microscale processes and macroscale transport.

The study explores how bacterial growth on oil droplets in marine environments can deform the oil-water interface, generating complex shapes and significantly enlarging the droplets. This deformation affects the droplets’ transport, as their rising speeds are significantly reduced. The research utilized a novel experimental setup called the “hydrodynamic treadmill,” which allowed for continuous and direct observation of stationary oil droplets in a lab setting. The study found that the deformed droplets rise slower than those without bacteria, due to increased drag force and decreased buoyancy.

My contributions to the project include sourcing various components needed to build the setup as referenced on the original paper designing a 100:1 and 5:1 geartrain system to control the speed of the chamber and the mounts for holding the setup. These resulted in the first round of data collection by observing the rise of oil droplets in a simulated ocean condition. In addition, I also worked on implementing an Arduino motor speed control.

Design

The hydrodynamic treadmill is based on a Stanford University paper. A modified version was designed and built to observe the bacterial growth on oil-water interfaces and the effects of the increase in bacterial mass on the rise of oil droplets suspended in water. This apparatus allowed for precise control over the droplets’ movement and their observation at high magnification to observe bacterial cultures that grow on oil droplets in oil spills in the ocean.

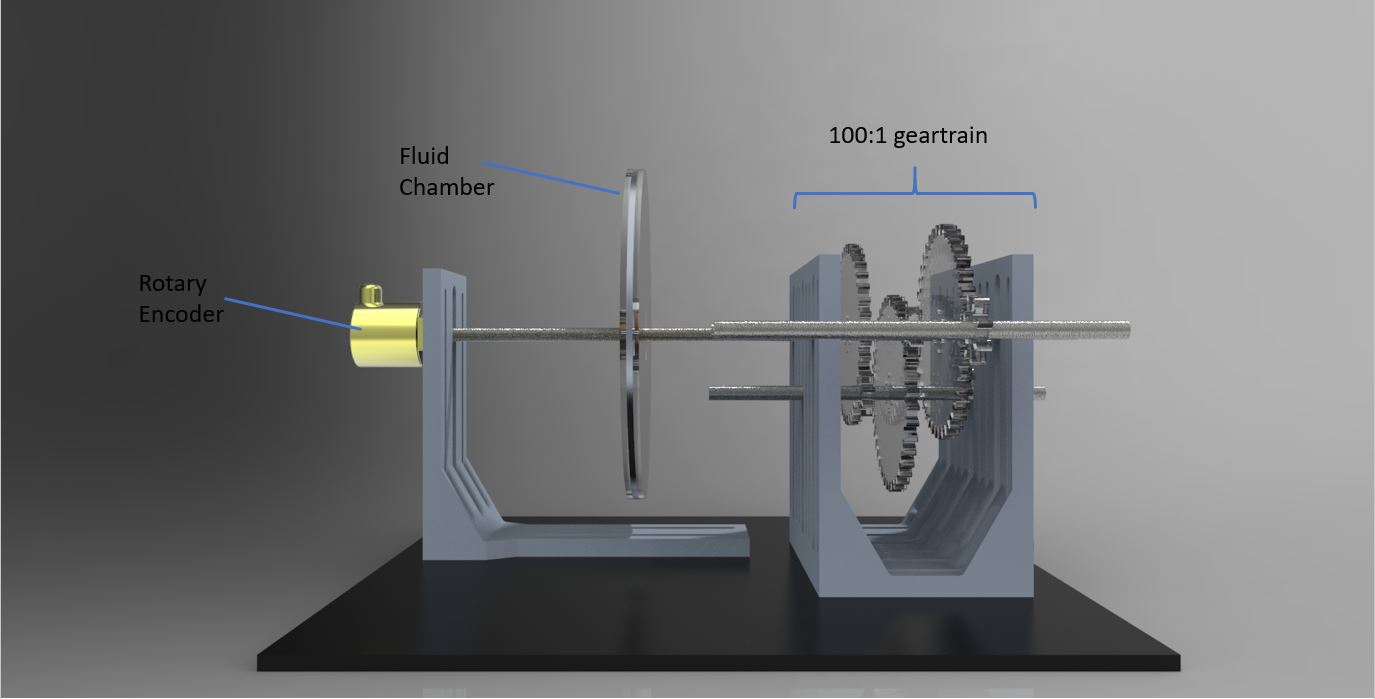

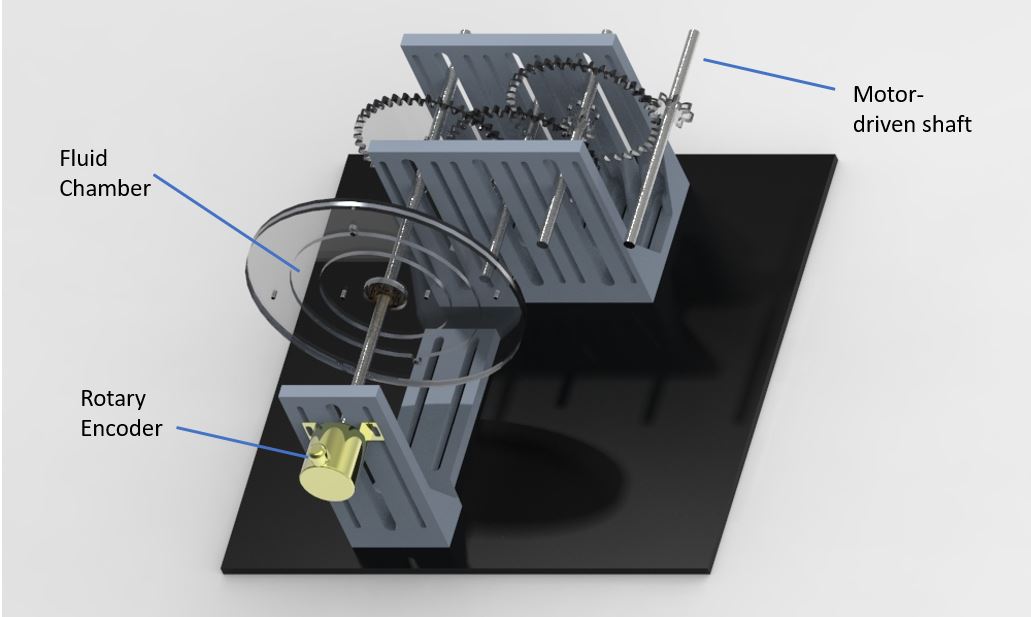

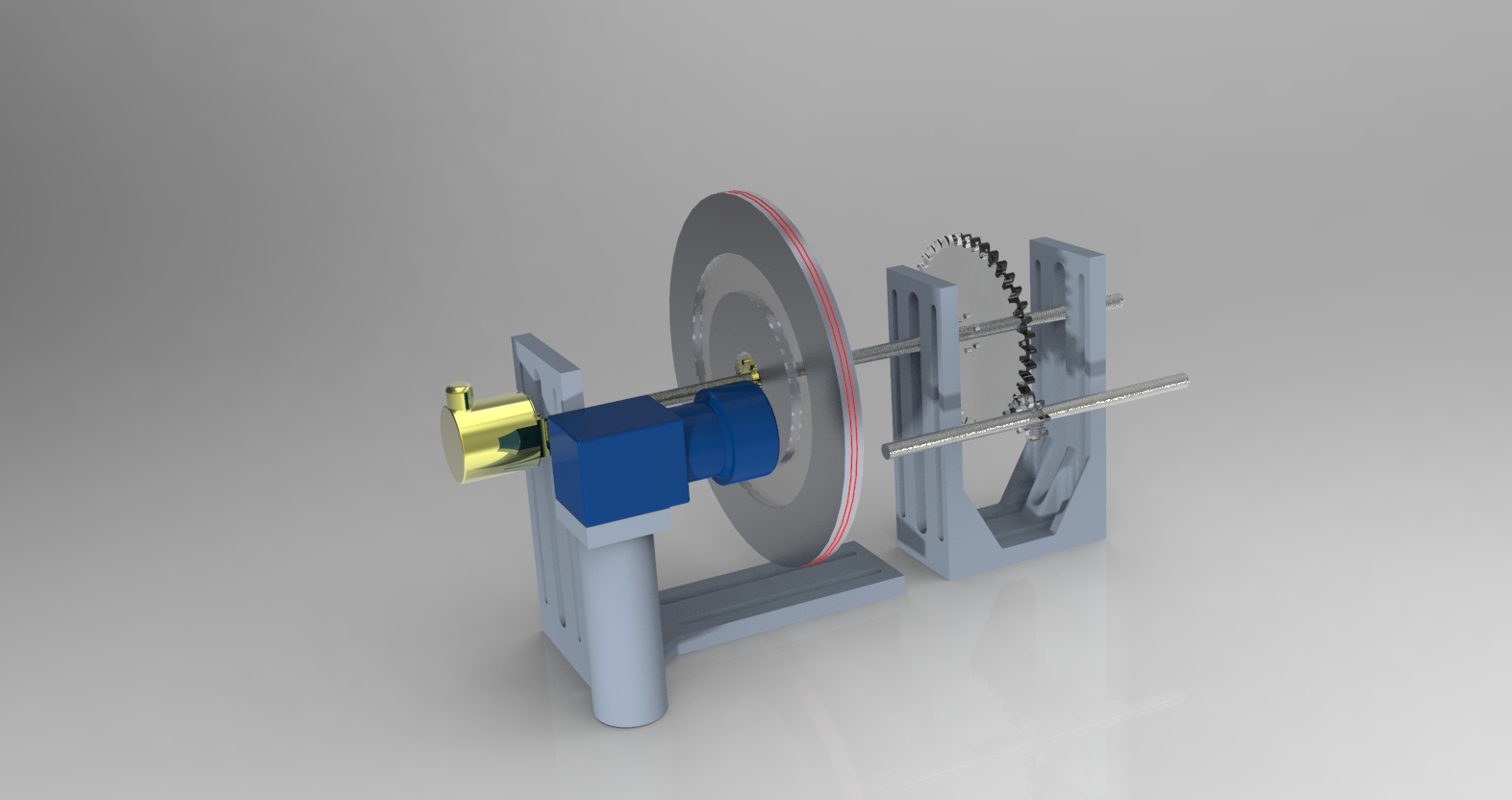

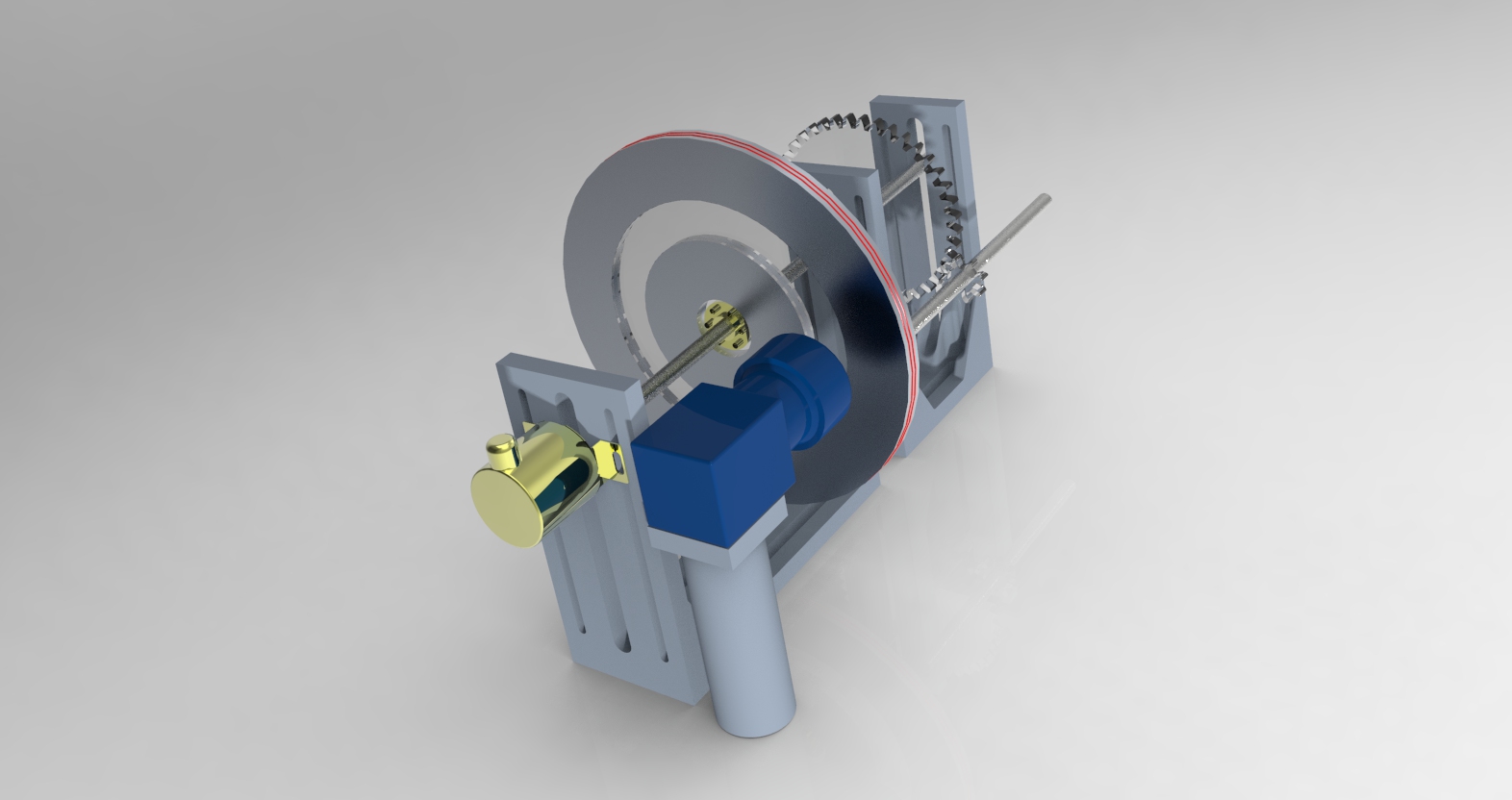

The designed setup with a 100:1 geartrain is shown in Fig.1. Note that the encoder is directly connected to the chamber shaft. The chamber itself is made of acrylic sheets with Aluminum rings in between and is sealed with adhesive. The gears are made of laser cut acrylic and the mounts are 3D printed. The 5:1 geartrain, shown in Fig.2 is also similarly designed and can be swapped between experiments. The parts in the figures are to scale and do not show any screws, bearings and hubs.

|  |

| |

Fig.1: Visualization of the apparatus with a 100:1 geartrain attached.

|  |

| |

Fig.2: Visualization of the apparatus with a 5:1 geartrain attached.

Current Setup

|  |

| |

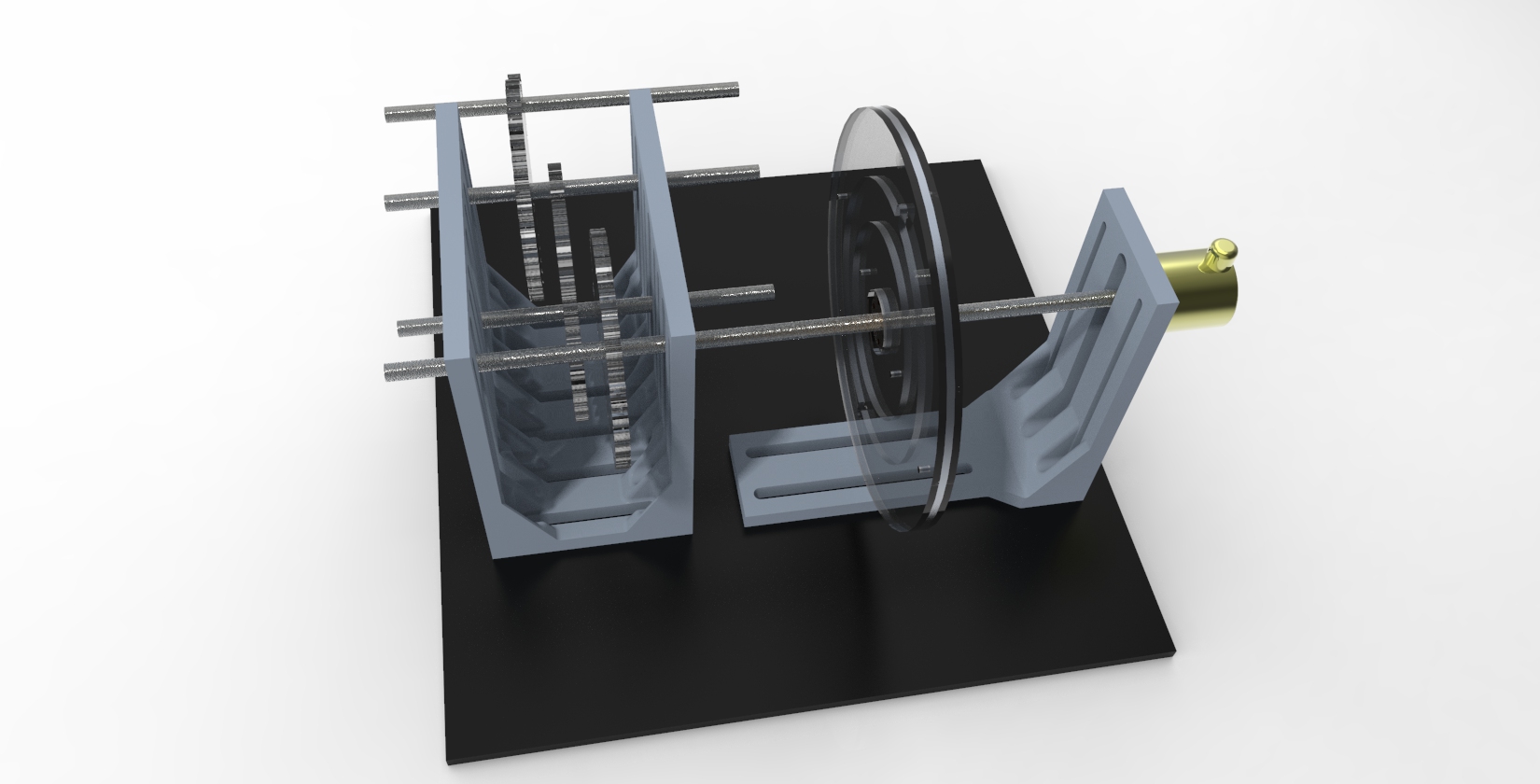

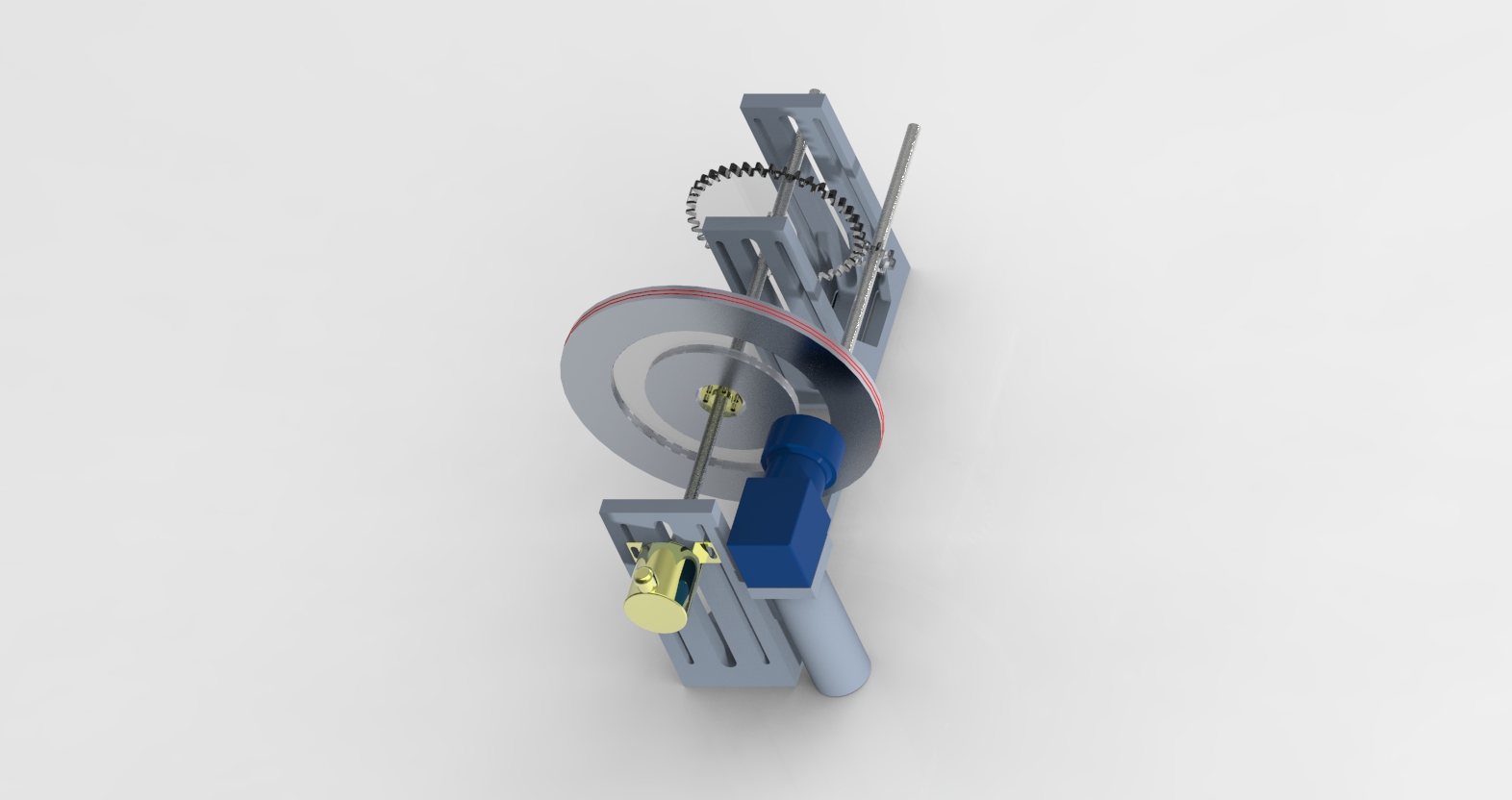

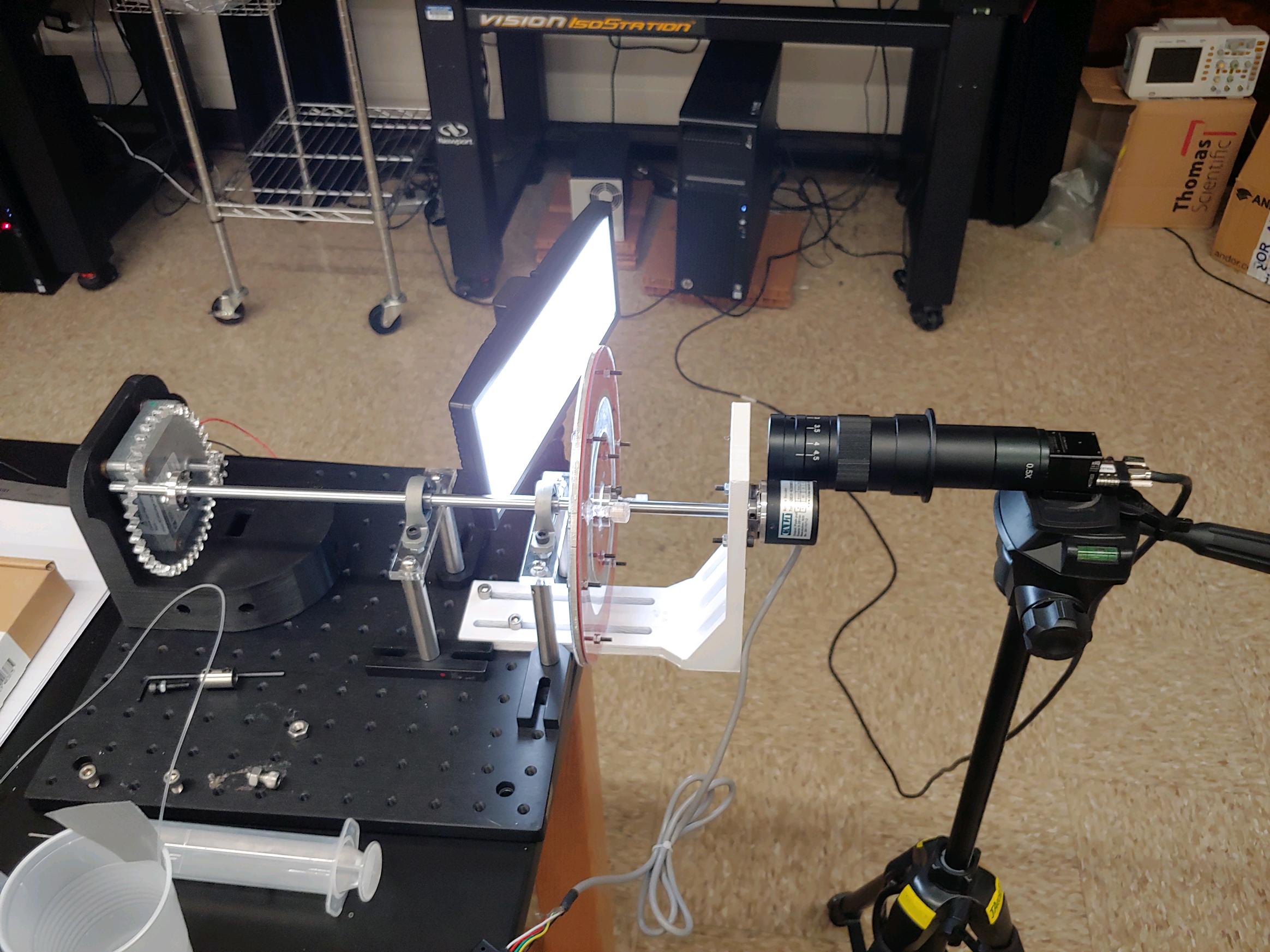

Fig.3: Current setup images.

Apparatus in operation

Results

This study revealed that droplets suspended in a cell suspension became colonized and deformed by bacteria, affecting their buoyancy and rising speeds. The hydrodynamic treadmill provided accurate measurements of these changes. The study also examined the composition and morphology of oil particles, finding that sinking particles consisted primarily of bacteria and biofilm with smaller oil particles. The composition of these aggregates was quantified using fluorescence microscopy.

Rising Droplet Videos

7% 20fps

38% rising 20fps

23% rising 20fps

The findings of this study are a significant step forward in understanding the microscale microbial processes that affect the transport of spilled oil. It was found that droplets of crude oil are significantly deformed and enlarged due to colonization by oil-degrading bacteria, leading to the formation of bio-aggregates at the droplet surface. This, in turn, reduces the rising speeds of oil droplets. The study emphasizes the importance of considering these effects in future models simulating the transport of spilled oil. Additionally, the research discusses the implications of bacterial colonization in the transformation and downward transport of spilled oil in marine environments.

Related Publication

Hickl, Vincent, Hima Hrithik Pamu, and Gabriel Juarez. “Hydrodynamic Treadmill Reveals Reduced Rising Speeds of Oil Droplets Deformed by Marine Bacteria.” Environmental Science & Technology 57.37 (2023): 14082-14089.

References

Krishnamurthy, D., Li, H., Benoit du Rey, F. et al. Scale-free vertical tracking microscopy. Nat Methods 17, 1040–1051 (2020).

Media Mentions

University of Illinois Mechanical Science and Engineering News: Juarez study of bacterial growth on oil droplets could improve oil spill mitigation